High Frequency PCB Manufacturers, High Frequency PCB Factory, High Frequency PCB Design in China

Toggle Navigation

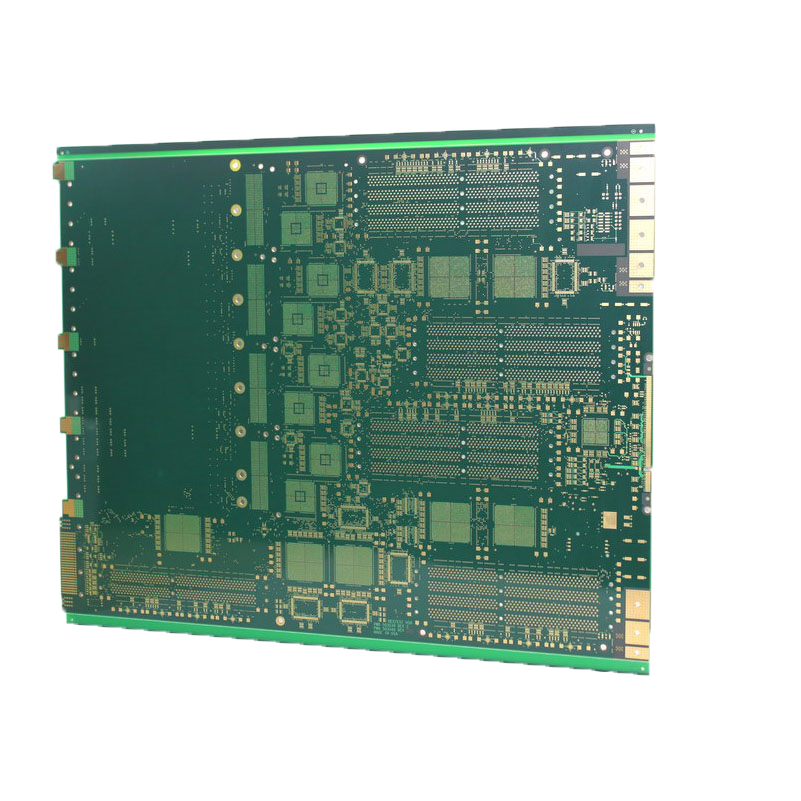

Phenomenal versatility: HDI boards are ideal where weight, space, reliability, and performance are primary concerns.

Compact design: The combination of blind vias, buried vias, and microvias brings down the board space requirement.

Better signal integrity: HDI incorporates via-in-pad and blind via technology. This helps in placing the components closer to each other which cuts down the signal path length. The HDI technology removes via stubs and therefore reduces reflections of signal and thus improving signal quality. It therefore remarkably improves signal integrity due to shorter signal paths.

High reliability: The implementation of stacked vias make these boards a super shield against extreme environmental conditions.

Cost-effective: The functionality of a standard 8-layer through-hole board (standard PCB) can be reduced to a 6-layer HDI board without compromising the quality.

Cost-effectiveness: when properly planned out, overall costs are reduced due to the lower number of necessary layers and smaller sizes/fewer number of needed boards when compared to standard PCBs. Faster time-to-market: Design efficiencies in HDI PCB production mean faster time-to-market. Because of the easy placement of components and vias and electrical performance, it takes a shorter amount of time to go through the design and testing process for HDI PCBs. Better reliability: Microvias have much better reliability than typical through holes due to the use of a smaller aspect ratio; they are more dependable than through holes, granting HDIs outstanding performance with better materials and parts.

Shortening the distance between devices and trace spaces, HDI PCBs allow for deployment of a large number of transistors for better performance in electronics while lowering power consumption. Signal integrity is also improved due to the shorter distance connections and lower power requirements. Other performance improvements over conventional PCBs include stable voltage rail, minimal stubs, lower RFI/EMI, and closer ground planes and distributed capacitance.